History

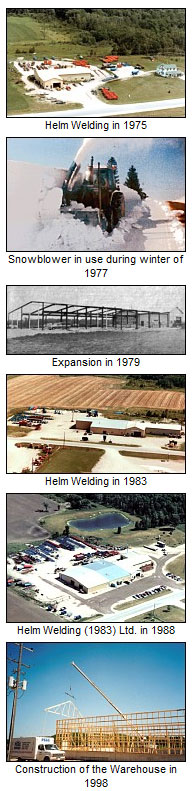

In the early 1960s, Art Helm began a small welding and machine shop located on the Helm family farm in Ashfield Township of Huron County in rural south western Ontario. The first building was constructed in 1968 on a lot located just south of Lucknow, Ontario. The main products produced at that time were snowblowers, gravity boxes, bale stokers and wagons, while providing repair and rebuild services to farm and industrial equipment.

In the early 1960s, Art Helm began a small welding and machine shop located on the Helm family farm in Ashfield Township of Huron County in rural south western Ontario. The first building was constructed in 1968 on a lot located just south of Lucknow, Ontario. The main products produced at that time were snowblowers, gravity boxes, bale stokers and wagons, while providing repair and rebuild services to farm and industrial equipment.

The 1970s saw bulk feed storage tanks, grain buggies and mixer feeders added to the product line. Several building expansions were completed during this time. By 1979, the size and manufacturing capacity had more than doubled. In 1983, the business became known as Helm Welding (1983) Limited. Products manufactured at this time were snowblowers, bulk feed storage tanks, mixer feeders, wagons and grain buggies with the addition of bale shredders and rotary mowers.

By the early 1990s, more dairy farmers were becoming aware of the benefits of going to a total mix ration feeding system. This saw a large increase in the sales of mixer feeders and the development of new models and refinements to the mixer feeder models. In 1998, the shares of Helm Welding (1983) Ltd. were sold from Art Helm to five employees of the company to ensure that the manufacturing facility and product line remained in Lucknow. As well, a warehouse building was added on the lot.

In the late 1990's, vertical auger mixers were added to the product line and proved to be very popular, further establishing Helm Welding's reputation of reliability and durability.

In the mid 2000's, a new product was developed for the initial purpose of spreading sand for cattle bedding. It was quickly realized that this product had many other applications including landscape work and golf course maintenance. The new Material Handler continues to find more uses.

In 2010, the product line was expanded to include pto driven Rotary Tillers.

In 2015, LuckNow underwent a re-branding with a new logo and other refinements. The mixer feeder line was streamlined and new features and options were added.

In 2016 a Bale Processor was re-introduced into the product line up. This product had been discontinued 20 years prior, but a significant market demand brought it back.

2017 saw the introduction of the Green Machine - a poultry mortality composter based on our time proven horizontal mixer. A truly economical and environmentally friendly approach to poultry mortality.

In 2018 Helm Welding celebrated 50 years in business!